dress

casual

fashion

safety

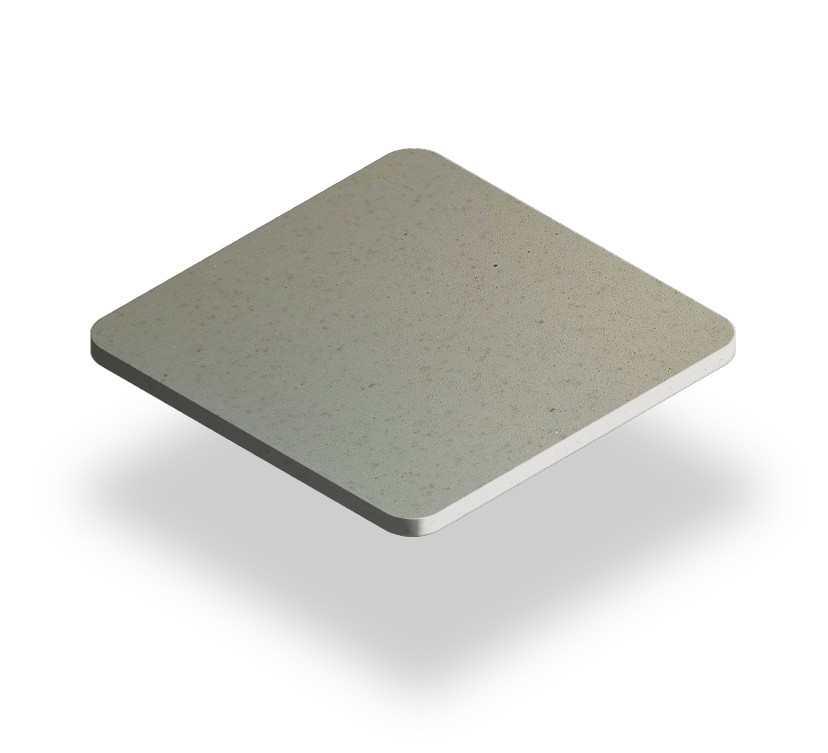

Open-cell flexible technical foam made out of aqueous dispersion of polymers (SBR and Poliisoprene), vulcanized and mechanized. Airfit formulations present excellent durability, smoothness and breathable properties. Due to their composition, they also have great anti-bacterial behavior.

Perfect for flat and light anatomic insoles for shoes that require high performance in limited space.

Breathble

Durability

Antibacterial

Softness

Memory Effect

Recycled

Global Warming

Global Warming Eutrophicathion

Eutrophicathion Water Scarcity

Water Scarcity Resource Depletion Fossil Fuels

Resource Depletion Fossil Fuels Chemistry

ChemistryIn the fashion industry many materials generate massive amounts of waste to produce the final product. We are committed to reduce to zero the amount of waste generated by transforming the product collected along its lifecyle to produce the same product achieving true circularity.