MAXIMUM COMFORT MINIMUM SPACE_

Designed for intensive use, Airfit technology maintains comfort during prolonged use. Our exclusive technical foam provides great strength and durability in a compact design, making it ideal for small spaces. Thanks to its cushioning system and soft touch, these foams are applicable to different uses.Attributes_

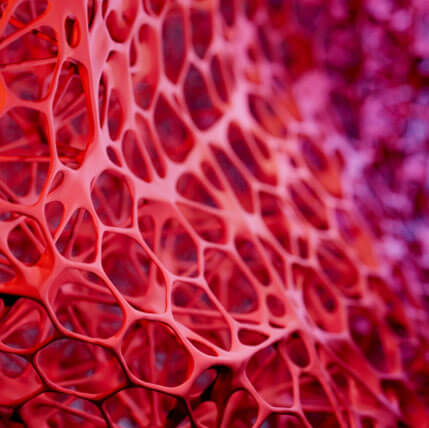

Cushioning

High shock absorption in the smallest possible area.

High resistance

Soft, ultra-light texture that endures wear and tear.

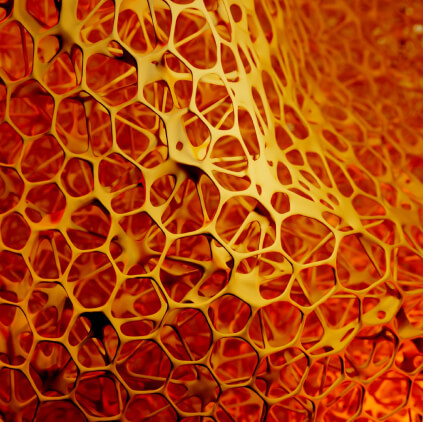

Breathability

Open-cell structure allowing the air to pass through.

Antibacterial

Prevents unpleasant odors thanks to its effectiveness against bacteria.

Footcare

Used for insoles that, because of their excellent capacity for cushioning and minimal thickness weight, promote comfort and wellbeing.

Footwear

It´s so small that it´s ideal for insoles in sandals or dress shoes.

Sporting goods

Used for travel yoga mats and for cushioning and breathability during movement.

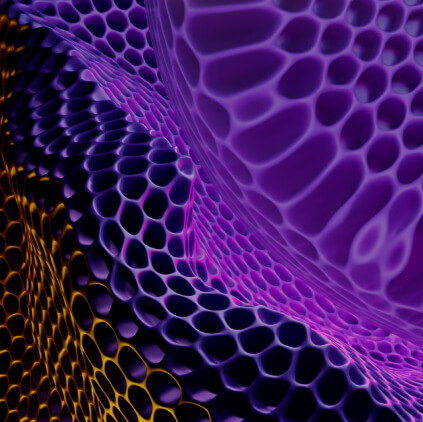

Acoustic insulation

High insulation, superior compressive strength, wear resistance, and environmental friendliness are all features of Airfit's acoustic technology.

Our commitment to Sustainability

Shifting to environmentally friendly materials and manufacturing techniques for foam solutions in order to minimize our impact on the environment.