MAXIMUM RESISTANCE AND LIGHTNESS IN EVERY STEP_

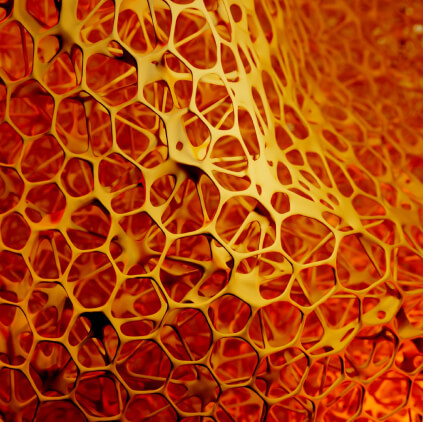

Cellfit is the perfect combination of strength and lightness. Its unique formula is designed to give you stability and balance, while harnessing energy in every movement. Its technical foam is designed to absorb impacts and, thanks to its open-cell structure, it is a highly breathable foam.Attributes_

Absorption

Absorbs impacts and protects against injuries.

Lightness

Lightweight foams.

Breathability

Allows air to pass through thanks to its open cell structure.

Footcare

It is used in insoles for its great cushioning capacity, which reduces the impact of the foot to achieve a smoother step.

Footwear

Gives a sturdy and safe footprint, which makes it perfect for daily usage and walking on a variety of surfaces.

Previous slide

Next slide

Our commitment to Sustainability

Shifting to environmentally friendly materials and manufacturing techniques for foam solutions in order to minimize our impact on the environment.